In the period from September 16 to 21, 2016, at the power unit No.2 of the Kola NPP, a planned repair of the node of welding the collector of coolant to the nozzle DU1100 of the steam generator PGV-440, aimed at prolonging its service life.

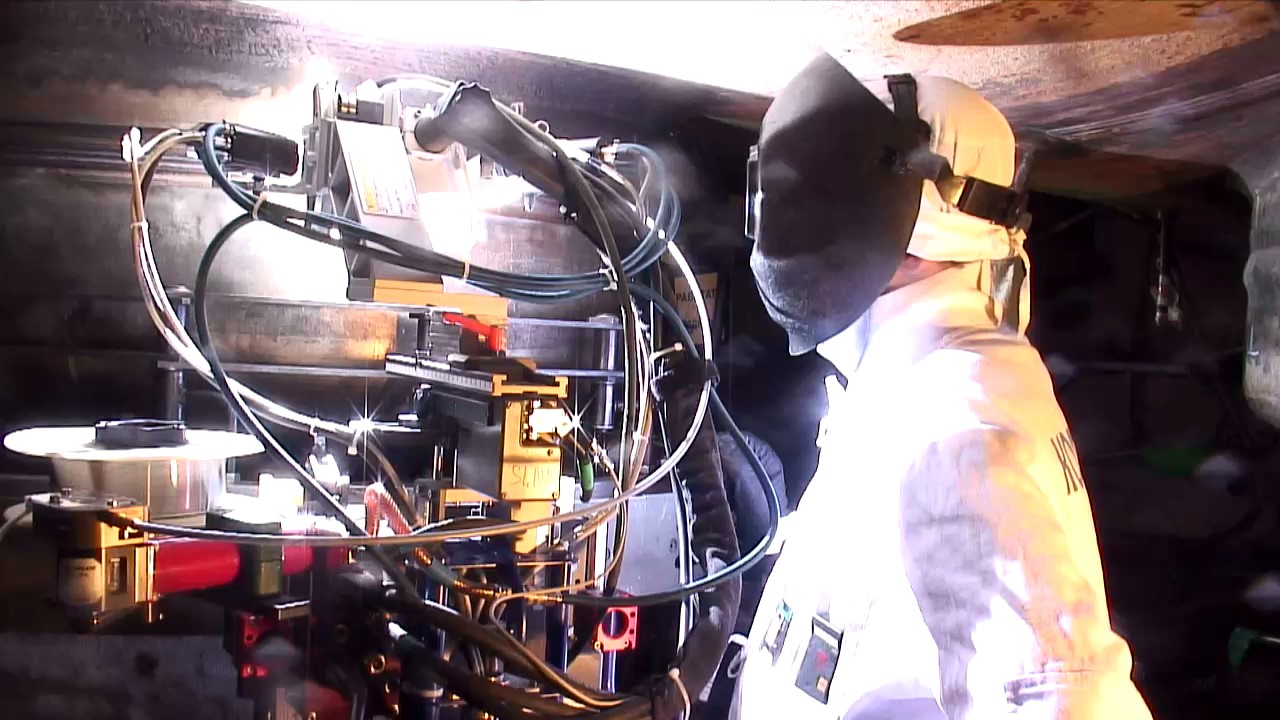

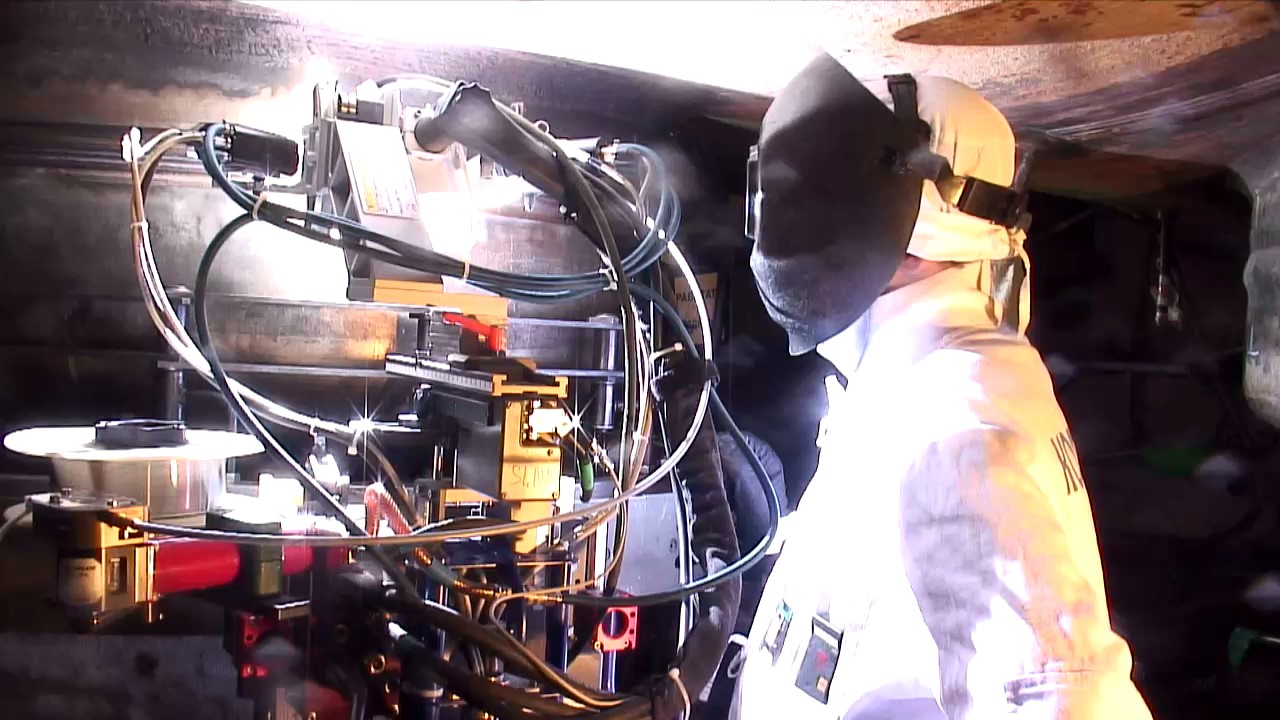

The repair was carried out using a unique technology of automatic welding with the help of a special equipment complex (SCE), created by JSC “GMZ “Himmash” to solve this problem. A feature of the technology is the welding of two synchronously operating welding machines on diametrically opposite sections of the seam.

The welded joint of the coolant collector with the nozzle DU1100 of the steam generator PGV-440 meets the requirements of the regulatory documentation. At the same time the time of welding is shortened.

Prior to this, neither in Russia, nor in other countries of the world did automatic welding for the repair of reservoirs of such steam generators at nuclear power plants.

The creation and successful testing of SCE for the repair of these welded joints is of great importance for restoring and prolonging the life of steam generators at other NPPs with VVER-440 reactors. The specialists of the Finnish energy company Fortum familiarized themselves with the new methodology.

The complex engineering of the CSE project was implemented between 2009 and 2016 by the specialists of JSC “GMZ “Himmsh” with the involvement of the companies POLYSOUDE S.A.S. (France), AOUT “POLYSOUDE Representative Office in Moscow” and JSC “NPO TsNIITMASH”.

Currently, together with the Centralized Repair Shop, the development of options for the modernization of CSE elements is being carried out in accordance with the additional technical requirements of the Kola NPP, which were identified during the Project of work production at Power Unit 2.